BMWi-project: FuelBand

BMWi-project: FuelBand – Broadening the range of fuels in modern biomass combustion chambers

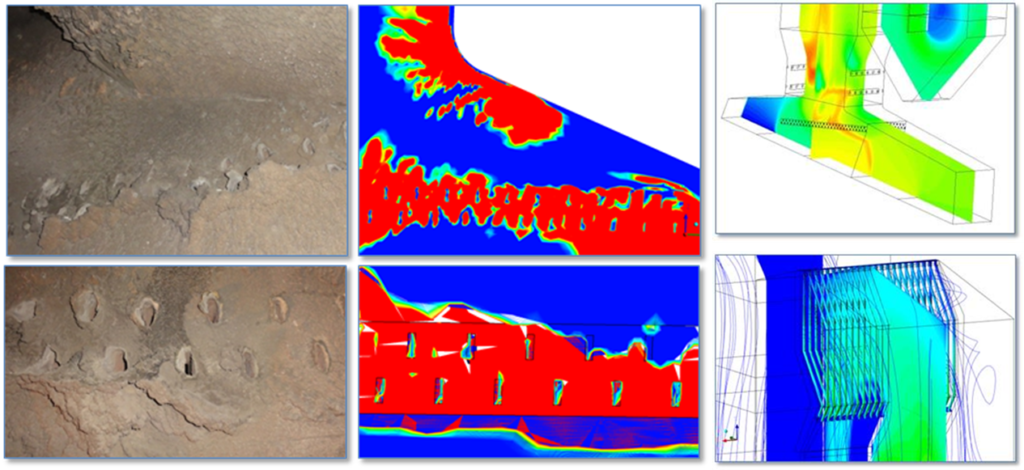

The project FuelBand uses a novel idea of CFD-simulation to predict slagging formation in biomass fuelled boilers.

Support Code: 03KB069

Term: 01.10.2012 – 31.12.2015

Website: click here.

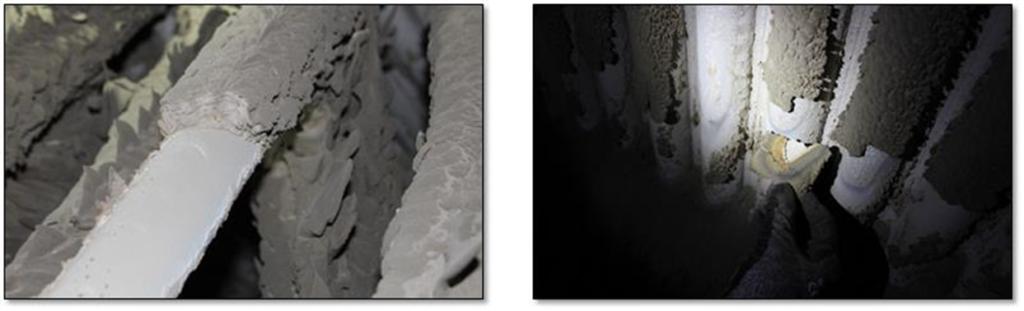

The project “FuelBand” focuses on the prediction of slagging formation in biomass fuelled boilers – one main objective is to allow a fuel flexibility in both existing and newly‑planned combustion chambers. The results of the project can lead to a better judgement of risks and possibilities when fuels with a high amount of ash or fine particles are applied.

The main objective is to describe and localise the slagging behaviour in biomass fuelled boilers in a simple, yet powerful and general model. By means of CFD simulations, the slagging formation can be described based on already available fuel parameters such as the proximate analysis, the fine particle content and the ash melting temperature as well as the combustion chamber geometry and residence time. Using a lab scale fluidised bed boiler, slagging experiments performed with a variety of fuels and fuel mixes allow model development and validation. In collaboration with plant operators and manufacturers, CFD was applied to further validate achieved results in four existing biomass power plants in the range of up to 30 MW thermal power. Based on CFD simulations, the operators’ experience and lab experiments obtained characteristic diagrams which potentially allow an easy transferability to a broad variety of boilers using different kinds of biomass fuels.

Contact:

Prof. Dr.-Ing. Jürgen Karl

Department of Chemical and Biological Engineering

Lehrstuhl für Energieverfahrenstechnik

- Phone number: 09115302-99021

- Email: juergen.karl@fau.de