BMWi-project Ash-to-Gas

BMWi-project Ash-to-Gas – Microbiological Methanation with hydrogen and nutrient solution out of the thermal gasification of biomass and its residues

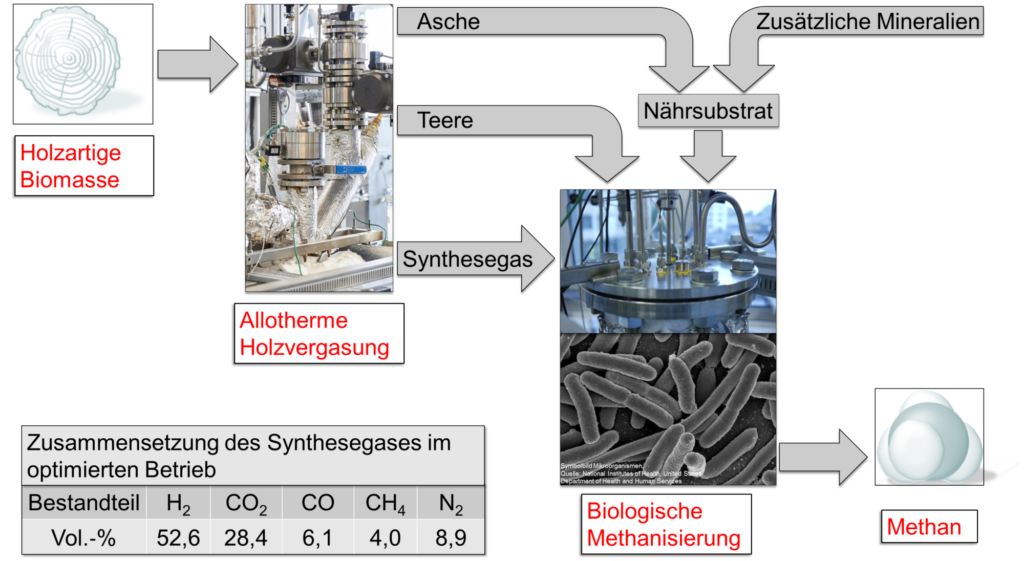

The BMWi-project Ash-to-Gas combines the allothermal gasifier with the biological methanation to produce methane out of biomass.

Support Code: 03KB097C

Term: 15.12.2014 – 31.05.2018

Biological methanation is an important approach to replace fossil fuels with renewables. Biological methanation describes the transformation of feed gas to methane through specific microorganisms.

Most biogas plants produce a product gas consisting mainly of methane and carbon dioxide.The latter is then separated by gas scrubbing to reach the requirements of the natural gas which are necessary for the system. A new approach is to convert carbon dioxide to methane through a metabolic process called methanogenesis. Hydrogen, which is further added to a fermenter, increases the hydrogen and carbon dioxide formation for certain strains of bacteria and archaea. This method is used in context with power-to-gas plants. A similar approach to provide hydrogen and carbon dioxide is to convert biomass with e.g. a heat pipe reformer or through TCR® process. The product gas is methanised in a downstream fermenter. The essential advantage, which is also the essential challenge of this method, is to provide the nutrients for the microorganisms through the ash of the gasifier. A basic scheme of the coupling between gasification and biological methanation is shown in Figure 1.

The project Ash2Gas is in cooperation with the start-up company Micropyros and the institute Fraunhofer UMSICHT (see above: partners). In cooperation with the project partners, a mobile fermenter is currently under construction and integrated into an allothermic gasifier at the chair in Nürnberg. The Proof of Concept is carried out on the TCR® gasifier at Fraunhofer UMSICHT. The nutrient supply is ensured either by supplying it directly to the ash particles from the gasifier or to the coke from the TCR® process respectively, or by a separate mixing of a slurry.

With this concept, the microorganisms are gradually accustomed to the product gas of the gasifier or to the TCR® process. The experiments are carried out with a feedstock based on wood, straw and road. The amount of carbon monoxide and long-chained hydrocarbons which can be converted and is further analysed. At the same time, the extent to which heavy metals (mercury, chromium, lead, cadmium) can be enriched by a biofilter effect in the fermenter is to be investigated. This makes it possible to deposit the bacteria safely on x and to withdraw them from the circuit.

Contact:

Department of Chemical and Biological EngineeringThomas Trabold, M. Sc.

Lehrstuhl für Energieverfahrenstechnik