BMWi-Project BiogasGoesHydrogen

BMWi-Project BiogasGoesHydrogen- Self-sufficient hydrogen production from biogas through reformation and CO combustion

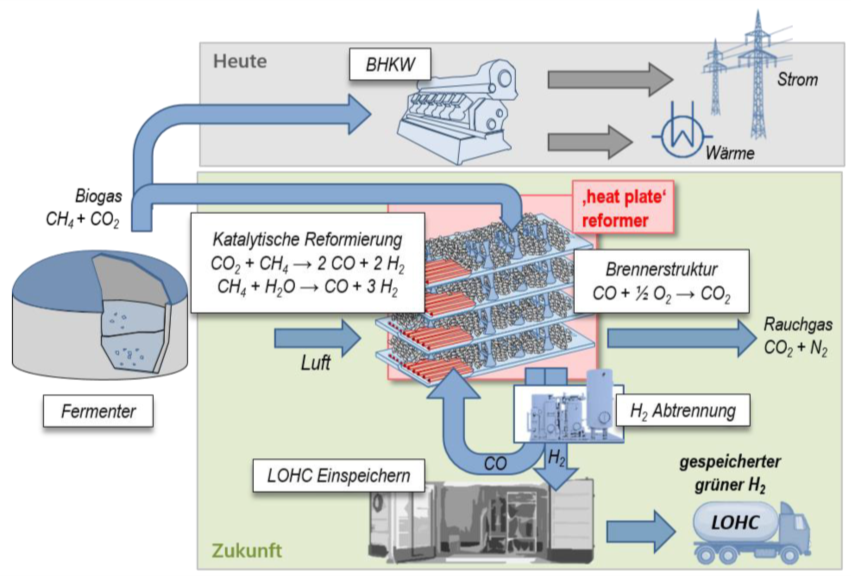

The BMWi-project BiogasGoesHydrogen investigates the reforming of biogas for self-sufficient hydrogen production without the use of electricity. By increasing the flexibility and economic optimization of biogas plants a contribution to sector coupling and hydrogen production is intended to be achieved.

Support Code: 03EI5435A

Term: 01.08.2021 – 31.12.2024

7. Energieforschungsprogramm

Förderbereich 3.7 Energetische Nutzung biogener Rest- und Abfallstoffe

For the transfer to a hydrogen-based, sustainable energy system, it is necessary to build up the corresponding capacities for hydrogen production. However, the currently most important process, water electrolysis, has the difficulty that the renewable electricity that is required for this is currently not available in sufficient quantities. In order to accelerate the transformation of the energy system and not to endanger the price stability and availability of renewable electricity, non-electricity-based technologies for the production of hydrogen are needed in the short to medium term.

In this context, the aim of the project is the self-sufficient production of hydrogen by reforming biogas. Thermochemical reforming is used to generate synthesis gas from which the hydrogen is subsequently separated. The required process heat is provided by internal combustion of the produced CO-rich lean gas. The LOHC technology is used to store and distribute the hydrogen.

In the first part of the project, suitable process conditions will be identified in order to achieve self-sufficient process control with maximum hydrogen yield. For this purpose, a stacked reactor design is being developed that is based on microstructured “heat plates”. Combustion takes place in these plates to provide the heat of reaction. The catalytic reforming zone is located adjacent to the heat plates. The possibilities of additive manufacturing are used here to achieve stable combustion and highly effective heat transfer. Subsequently, the feasibility of the concept is demonstrated by the implementation and experimental operation of an application-oriented system.

In a separate part of the work, the economic viability is shown by means of a technical-economic analysis. In addition to the contribution to hydrogen production, this is intended to give biogas plants an economic perspective after the expiration of the EEG compensation.

Contact:

Department of Chemical and Biological EngineeringAlexander Feldner, M. Sc.

Lehrstuhl für Energieverfahrenstechnik