BMWi-Project: KonditorGas

BMWi-Project: KonditorGas – Industrial process heat generation by catalytic conditioning of synthesis gases

This project is to show a new way to substitute the so far predominant supply of (high temperature) process heat by fossil fuels with climate-friendly biogenic synthesis gases from the thermo-chemical gasification of biomass or biogenic residual and waste materials.

Förderkennzeichen: 03EI5417A

Laufzeit: 01.09.2020 – 31.08.2023

For economic reasons and to reduce CO2 emissions, substitution of natural gas with energy from biogenic feedstock is desirable for many energy-intensive processes. Especially against the background of the CO2 taxation from 2021 onwards, this will be particularly important for small and medium-sized enterprises (SMEs) to rely on alternative methods of generating energy for their production processes. The direct combustion of biomass is mostly out of question for many melting, burning and other high temperature processes, because necessary adiabatic combustion temperatures are not reached and the control of solid fuel firings cannot be realized sufficiently fast and flexible and fly ashes can impair the product. On the other hand, processed biogenic synthesis gases from gasification could be used in existing burners and furnaces with only minor modifications. Ideal for such processes is the production of Substitute Natural Gas (SNG) from solid biomass. In this process, biomass is first thermo-chemically gasified and the resulting synthesis gas is then processed to current natural gas standards by catalytic methanization and gas treatment.

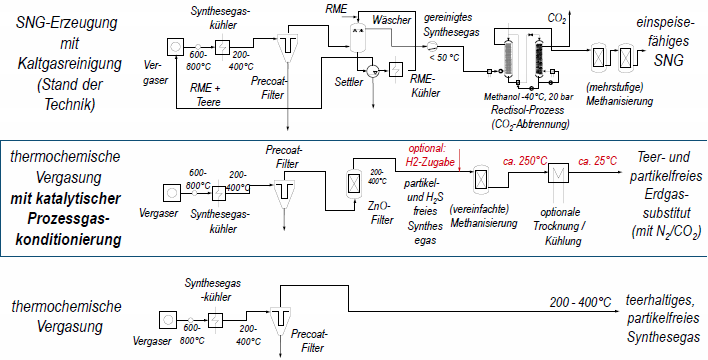

For many industrial processes, however, it is not necessary to treat the synthesis gas produced during biomass gasification to natural gas quality. Instead, the gas quality can be individually adapted to the requirements of industrial processes and burners by partial methanization. This results in a significant technical and economic simplification of the process chain of gas treatment and synthesis compared to the production of SNG that can be fed into the grid (see Figure 1).

In order to provide plant manufacturers and operators with the motivation to implement these processes, the project aims to demonstrate the complete process chain consisting of biomass gasification, preparation of the synthesis gas and combustion in commercially widely used burner systems. Two different process chains will be realized. On the one hand, synthesis gas is to be produced via allothermal gasification using a 100 kW Heatpipe-Reformer (see Figure 2) at the Chair of Energy Process Engineering, while at the project partner DBFZ Leipzig (German Biomass Research Centre) the process gas is produced autothermal using a fixed bed gasifier.

The gas properties such as calorific value, Wobbe index, etc. of the gas are to be adapted to the respective application by (partial) methanization downstream of the gasification in order to ensure sufficiently high process temperatures at all times. Decisive for the suitability of biogenic gases for the respective processes are not only calorific values and the adiabatic combustion temperature, but above all ignition limits and laminar flame velocities.

From the results of the analysis of the resulting process gases, the project partner E-Flox will provide a gas burner adapted to the properties of the produced process gas. Furthermore, TestNet will take over the design and conception of the required hot gas control system for the planned process chain and complete it. After successful test campaigns in laboratory scale at the EVT as well as at the DBFZ, the proof of concept with a commercial small-scale biomass gasifier is to take place in field tests.

The overall objective of the project thus makes a contribution to CO2 reduction in industrial high-temperature heat use, for which hardly any technologies for using biomass are currently available.

Ansprechpartner:

Department of Chemical and Biological EngineeringChristian Wondra, M. Sc.

Lehrstuhl für Energieverfahrenstechnik